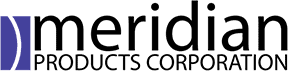

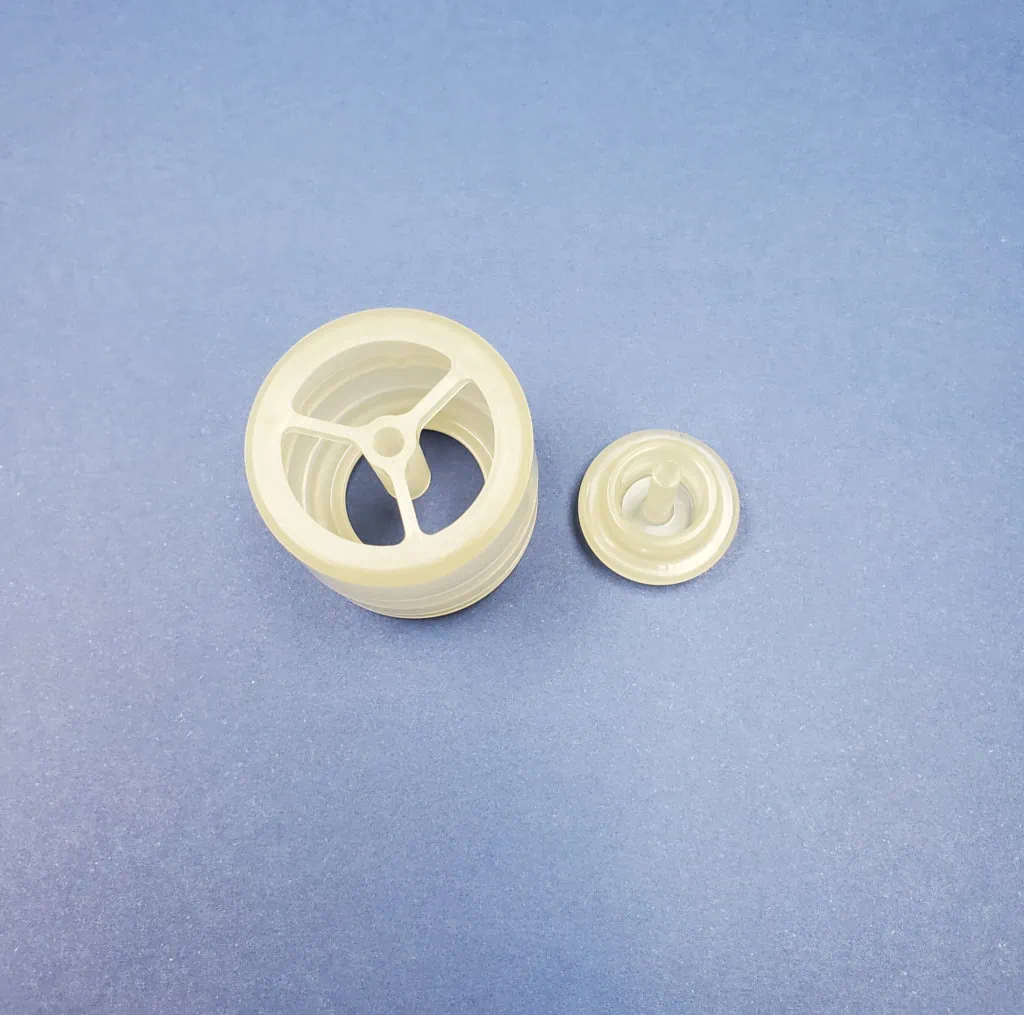

Our metal replacement flow moldings provide lighter weight, improved corrosion resistance, and intricate shapes. Embraced across automotive, industrial, and consumer sectors, they optimize performance and cut production costs. Positioned at the forefront of manufacturing, we prioritize cost-effectiveness, weight reduction, and design flexibility with our expertise.

Advantages of Metal Replacement Molding

Shifting from metal to plastic components can propel manufacturing and product performance forward in multiple ways:

- Numerous engineering thermoplastic polymers surpass aluminum and other metals in weight and strength, thus delivering manufacturing savings and enhanced functionality.

- Thermoplastic resins eliminate the need for finishing, welding, or machining operations typically associated with die-cast, stamped, or machined metal parts.

- Plastic parts can be molded in specific colors, negating the necessity of painting metal components.

- In many applications, sound and vibration-dampening properties are inherently superior to metals.

- Recyclability is a significant advantage when transitioning from metal to plastic.

Plastic part designs frequently demonstrate superior structural efficiency compared to their metal equivalents, enabling the optimization of features that would be unfeasible with traditional metal components.

Our range of engineering resin options ensures resilience without sacrificing structural integrity or essential properties, even in environments susceptible to corrosion or chemical exposure. This capability mitigates the risk of metal component failures over time, providing enhanced product reliability and longevity.

Materials Used in Metal Replacement Molding

Numerous resin options are materials used in metal replacement moldings. At Meridian Corporation, we offer a range of choices, from high-end engineering resins like PEEK, PPA, polyetherimide, and PPS to more common grades like long glass fiber polypropylene. These materials often replace short glass fiber nylons in automotive applications.

Our selection also includes nylon resins, available in various glass-filled or filler-injected forms, which are adequate substitutes for metal across diverse applications. With our extensive range of resin options, Meridian Corporation provides comprehensive solutions to meet the evolving needs of the industry.

Applications and Industries

Metal replacement flow moldings are rapidly gaining traction in the automotive, aerospace, and electrical industries. Automotive manufacturers leverage thermoplastics for lighter, more fuel-efficient vehicles, while aerospace benefits from enhanced efficiency and longevity. Polymers’ insulative properties and design flexibility are invaluable in electrical systems.

As demand grows for lightweight, durable materials, metal replacement moldings are set to redefine manufacturing standards. Meridian Corporation leads this transformative technology, offering injection molding metal replacement. Our solutions enhance performance, efficiency, and reliability across applications.

Meridian Corporation’s Commitment to Excellence

At Meridian Products Corporation, our dedication lies in providing outstanding quality across all our offerings. This commitment is ingrained in our manufacturing process, from meticulous material selection to the final product’s delivery. We adhere to strict testing protocols and robust quality control measures to guarantee that our metal replacement moldings meet and surpass industry standards.

We take immense pride in our ISO 9001:2015 certification, a testament to our steadfast pursuit of excellence. This certification highlights our relentless commitment to quality management systems, ensuring consistent product performance and customer satisfaction.

Contact us now to experience the superior quality and reliability that Meridian Products Corporation can bring to your metal replacement molding needs.