Molding processes using bioresins that are compostable and degradable have emerged as an important “green” alternative to traditional polyurethane based plastics.

Meridian is experienced in the production of plastic components molded from bioresins.

Why Biodegradable Resin Molding?

While bioresins will never completely eliminate the problem of plastic waste (since they are not suitable for all product applications), they can nevertheless be an important facet in reducing pollution and waste in some instances. Petroleum-based plastic production by some estimates cost the world economy $75 billion each year in natural capital, so anything to mitigate that cost is an important factor.

Advantages of biodegradable resin molding include:

- Slowing input into methane producing landfills, plus leaving more greenhouse-gas emitting petroleum in the ground. Small additions of renewable, biobased content can help significantly reduce harmful emissions, thereby lessening the environmental impact of products we use every day.

- Easing our reliance on non-renewable resources.

- Variety of sustainable, compostable, and eco-friendly grades currently available.

- Recyclability is a definitely an important process in lessening the impact on the environment, but the use of bioresins will have even a greater effect, since there tends to be inconsistency in recycling programs. The U.S. generates over 30 million tons of plastic waste each year, of which only about 10 percent is recycled. The rest is sent to landfills for generations to come. Compostable bioplastics return to organic matter through the composting process in as little as 3 months, leaving no toxins or residue, unlike petroleum-based plastics.

Materials Used for Bioresin Molding

There are many resins available that are suitable bioresin options, including PLA (Polylactic acid, made from renewable plant sources such as corn) and PHA (polyhydroxyalkanoate) both of which are primarily compostable.

Similar Production Cost

As processes continue to develop to streamline manufacturing, the cost of using bioresins is in approximately the same range as when using traditional plastics.

Applications and Industries

Bioresin molding is particularly suitable for the following industries:

- Food industry

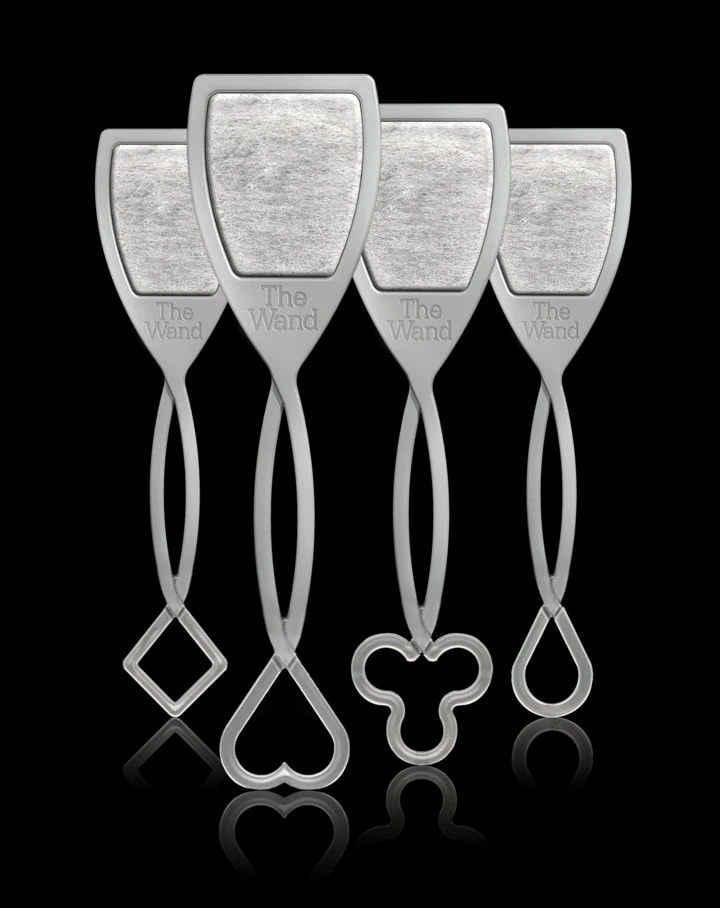

- Consumer products

Examples:

- Disposable utensils

- Toiletries

- Straws

- Plastic bags

- Single use food containers