Medical Devices and Components

Medical devices and components require a particularly specific production process, such as medical injection molding, in order to satisfy stringent medical and quality requirements.

Meridian is among the top medical injection molding companies that prides itself on its excellent service, production processes, quality planning and design support, and post-molding capabilities to provide solutions that meet the expectations of medical industry customers and ensure that requirements in this industry are met.

What is Medical Device Injection Molding?

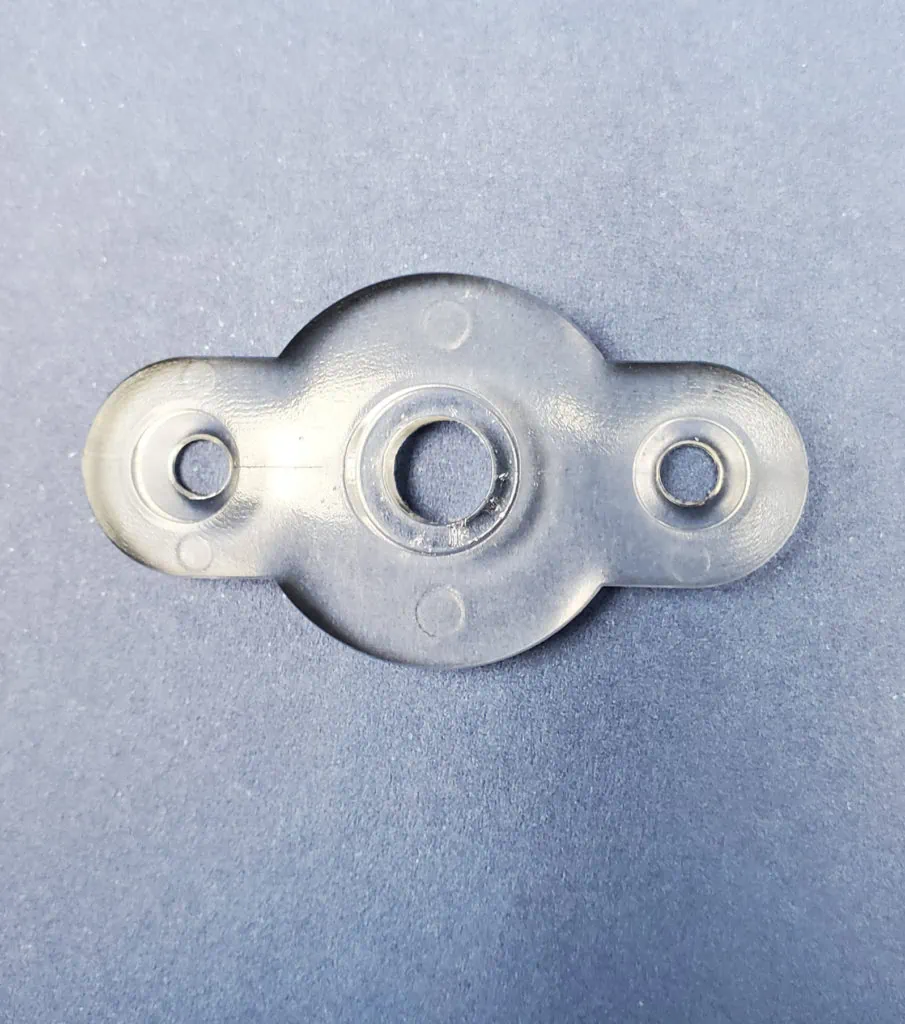

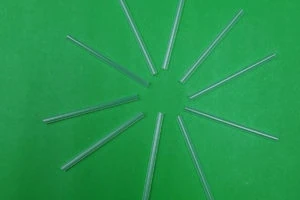

Medical device injection molding is a manufacturing procedure that produces consistent-quality plastic devices and components for medical use. The process involves melting the biocompatible plastic resin pellets until they become molten and injecting them into a mold to create the desired shape or form. The mold is then cooled, and the plastic solidifies, resulting in a rigid, strong, and quality plastic product.

Medical injection molding can manufacture FDA-approved medical devices and is employed during rapid prototyping in developing new medical devices or components to be sent to the FDA for approval. The process can efficiently achieve complex shapes and designs, making it ideal for creating intricate medical devices with high precision and consistency.

Benefits of Medical Injection Molding

As one of the leading medical injection molding companies, we can provide top-quality results in a shorter time frame through medical device injection molding. It facilitates rapid production time, allowing us to deliver injection molded parts, components, and products on or before the deadline.

More of its benefits include:

- High-quality medical device components

- Lower labor costs and substantial savings

- Superior strength and durability

- Design flexibility for complex parts

- Reduced risk of contamination

- Consistent and precise production process

Material Specifications

Material recommendation and selection is a very important step of medical injection molding.

Our clients begin with the submission of a comprehensive material requirement form in order to identify materials that meet their specifications, including flammability, temperature use ranges, color, impact requirements, etc.

We have a broad supply base to draw from, ensuring that the exact materials, such as antimicrobial grades, FDA-compliant resins, and colorants, are utilized.

Anti-microbial Protection

Current events require a growing need to provide anti-microbial plastic products, whether it be inherently in the resin, or with an additive for anti-microbial requirements.

For example, studies have found serious pathogens, such as streptococcus and E. coli, on phones and other handheld devices; so the importance of protecting cases, game controllers, remotes and other accessories is vital.

This is an evolving market, with an increasingly available variety of engineered and enhanced-grade commodity resins that will meet specifications.

We are assisting our customers by evaluating and selecting the most suitable resins for their product requirements.

Examples of Applications

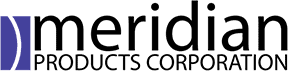

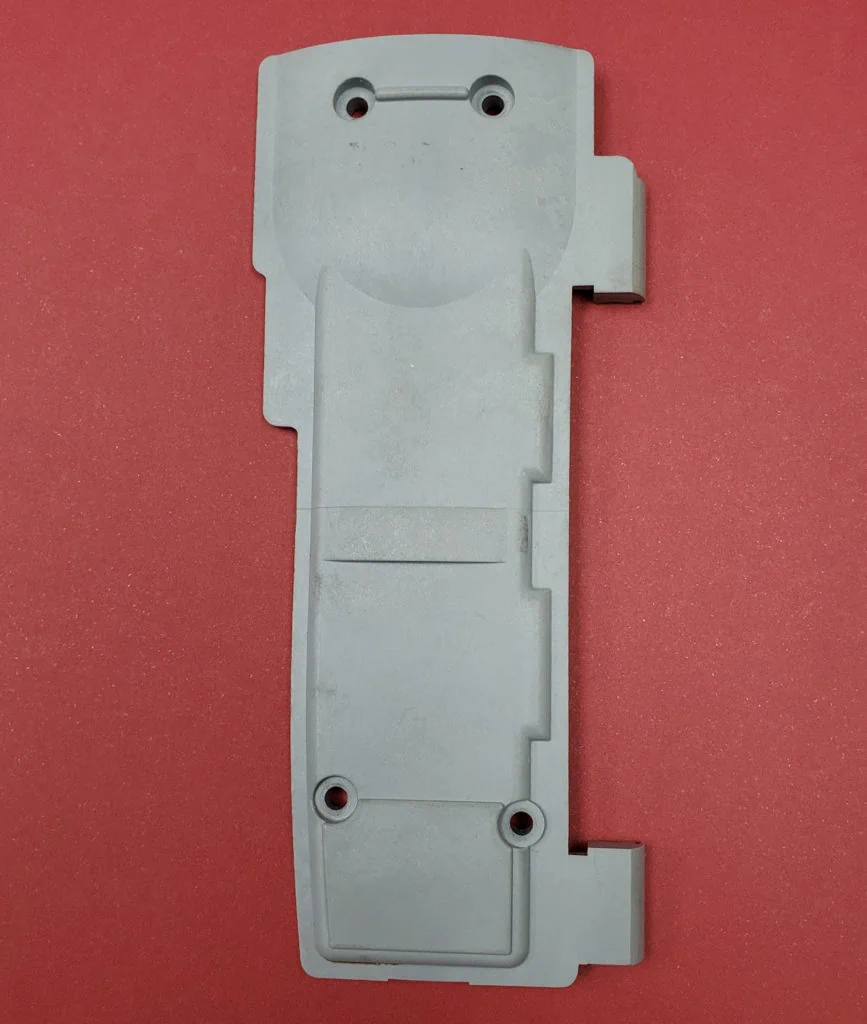

Customers come to Meridian with a particular problem or product to be produced and we work together with them to produce the highest quality end products through cutting-edge equipment used in medical device injection molding.

Some examples include:

- Patient monitoring for vital measurements

- Wound care

- Hospital room infrastructure devices

- Drug delivery systems

- Veterinary monitoring devices

Quality

As an ISO 9001:2015 registered company, we have adapted requirements that meet ISO 13485 when required by our customers.

Choose Meridian to Develop FDA-Approved Medical Devices Today

Meridian is among the top medical injection molding companies that prides itself on its excellent service, production processes, quality planning, design support, and post-molding capabilities. We aim to provide solutions that meet the expectations of medical industry customers and ensure that requirements in this industry are met.

With our medical injection molding process, you can trust us to achieve optimal results that meet your expectations and save lives. Contact us today to learn more about our capabilities, or you may also request a quote to kick-start your project immediately!