Meridian Products Corporation specializes in overmolding, a type of insert molding method that combines two or more components molded over one another to create a single, strong component. Overmolding is a highly advanced manufacturing process that requires precision and expertise to produce high-quality and reliable results. Fortunately, our team has years of experience and knowledge in achieving consistent and superior quality outcomes based on your project’s requirements.

Over Molding, Insert Overmolding Process and Applications

Overmolding is an insert molding process whereby one material is molded over a second material. The initial “substrate” is commonly the harder plastic of the two resins. Once the “substrate” is molded, it’s placed into another mold cavity, and the “over-mold” resin is injected into specific surface areas of the substrate to achieve the intended design and usage.

This “overmolded” resin is typically a thermoplastic elastomer (softer feel), although other resin grades provide a softer feel. There are many applications where these types of products are chosen to be overmolded with a softer resin to aid comfort, ergonomics, cushioning, shock absorption, and functionality.

Benefits of Overmolding

Overmolding is a multi-step insert injection molding technique that aims to create an injection-molded product free from defects while achieving complex and creative designs. By doing so, it provides numerous benefits, such as:

- Custom plastic parts: The main advantage of overmolding is it allows for the design and creation of custom plastic parts for almost all industries. It can create a combination of plastic-plastic or plastic-metal products with excellent tolerance and dimensional quality.

- Better product performance: Adding another resin material significantly improves the properties of the final product since it utilizes two different materials with unique characteristics, such as waterproof, heat resistance, durability, and impact resistance. Therefore, it leads to better product performance, durability, and functionality.

- Cost-effective: Overmolding eliminates the need for additional assembly or secondary operations, reducing labor costs and increasing production efficiency. It also requires less material and reduces waste, making it a more cost-effective manufacturing method.

- Aesthetic appeal: Overmolded products have better surface finish and color options, allowing manufacturers to create attractive designs that match their brand image or customer preferences.

Material Selection

When overmolding plastic resins, proper material selection is critical – the two resins must be compatible. Resin suppliers provide guidance on which thermoplastic elastomers (the softer plastic) or other resin grades will bond to particular substrates depending on which resin grade is used to mold the substrate. Different hardness criteria are determined by the functionality or feel needed for an application. The range of durometers can be from 15 Shore A (very soft) to 90 Shore A (hard but still offers some softness dependent on wall thickness).

If the proper materials have been chosen, the two materials bond together chemically and/or mechanically. This overmolding injection molding process yields a strong finished piece with a long life. In many cases, this process can be less expensive than post-molding processes.

Using Over Molding for Design Enhancement

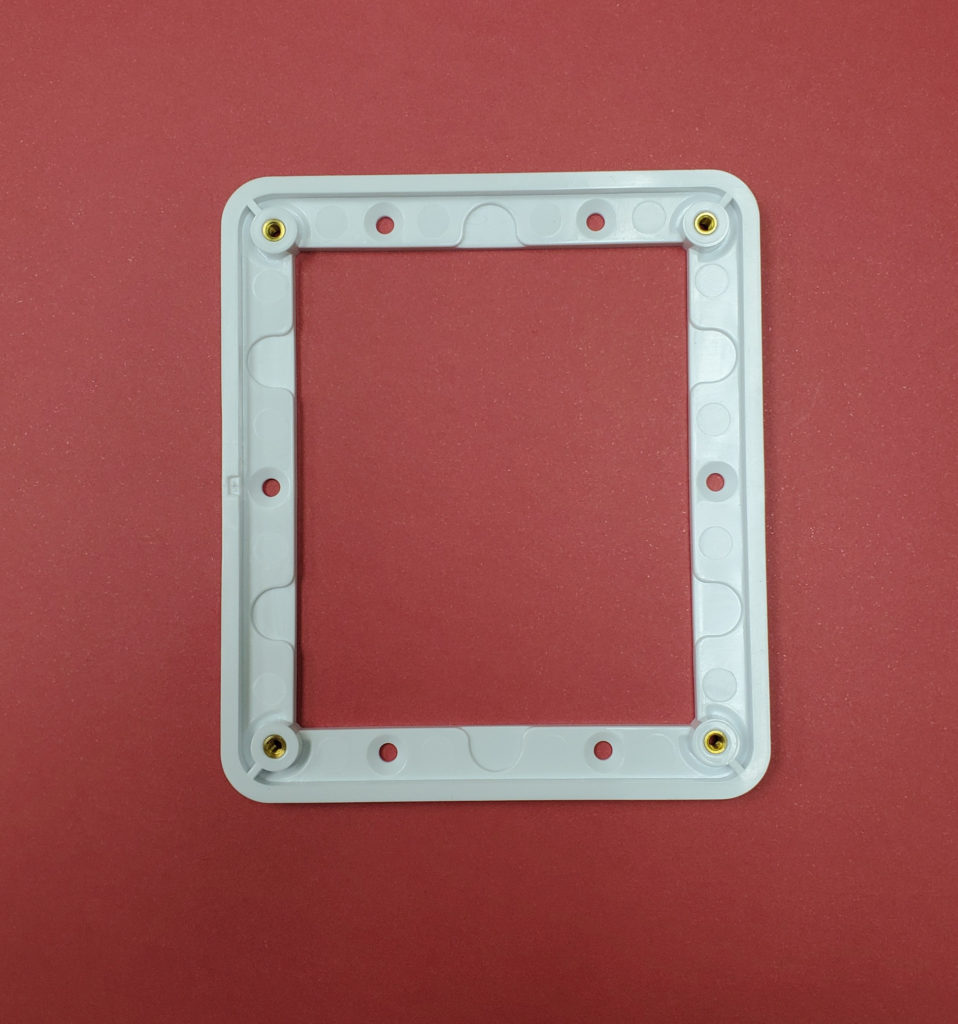

Meridian also overmolds metal components for added design enhancement, such as brass inserts or other metal components. Depending on part design, overmolding may be feasible where post-molding operations such as ultrasonic welding are not viable.

Overmolding processes lend itself to multiple industries and applications, such as:

- Toys

- Petroleum industry components

- Therapeutic tools

- Musical instrument aids

- Consumer filtering

- Toothbrushes

- Handheld tools

- Lawn equipment

- Electronic cases

- Computer mice

Let Meridian Work on Your Insert Molding Projects Today

With the simplicity and cost-effectiveness insert injection molding offers, manufacturers and clients have benefitted from the overmolding technique. If you’re interested in using overmolding for your next project, trust Meridian’s expertise and experience to deliver high-quality results that meet your specifications and requirements.

Contact us today to learn more about our overmolding injection molding services. Request a quote, and our team will develop a solution based on your project’s needs!