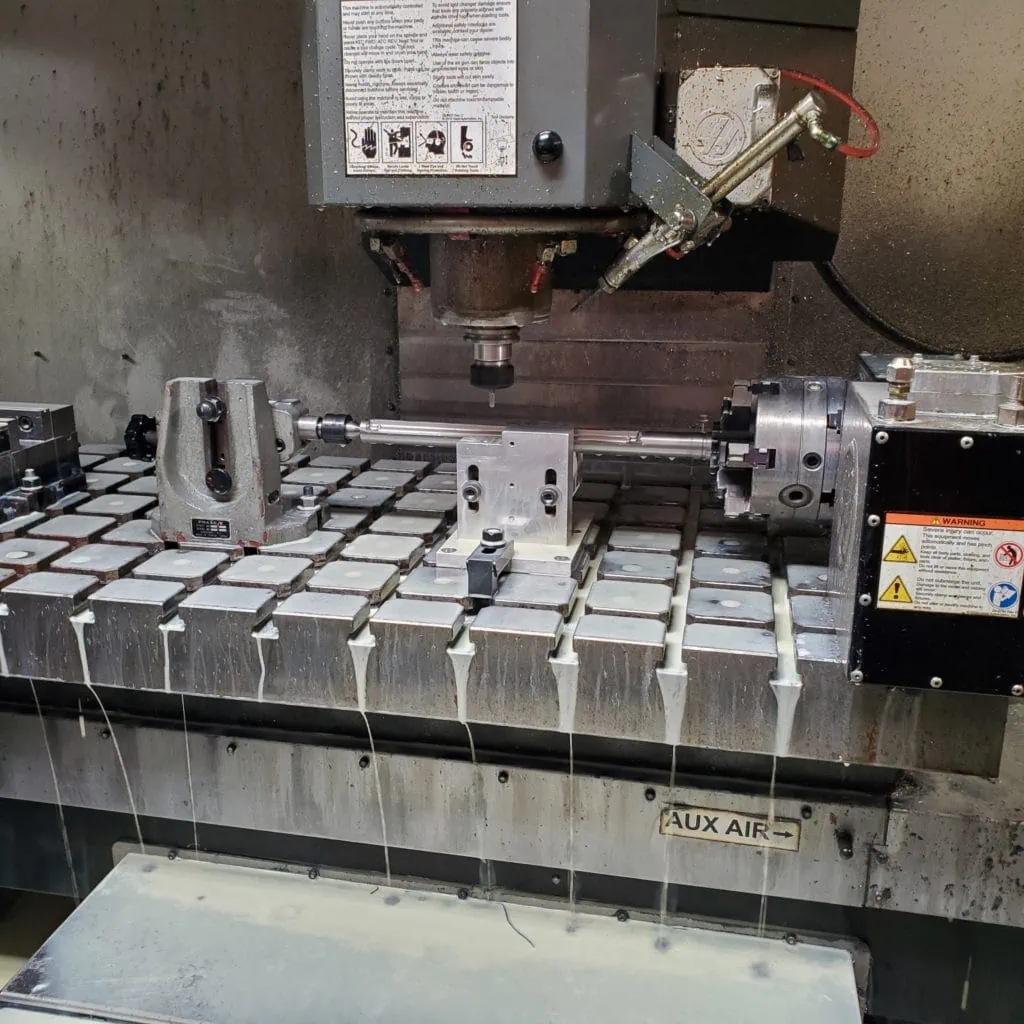

Meridian Products Corporation is a true turnkey manufacturer. We have 40 years of experience in our core competency, plastic injection molding. Meridian’s capabilities extend far beyond the injection molding process to encompass every stage of production.

Design

Do I need to have a detailed design ready?

Not all manufacturers advertising themselves as “turnkey” offer design assistance. We can assist you with the initial design and planning stages of your molding process. With an expert staff of molders and engineers, our team can help you finalize part designs to maximize quality and production efficiency.

If you have a completed design, it can be submitted to us as is. We can either approve it as is or make suggestions to help expedite production or improve end quality of the part. Generally, design evaluation and approval can take four to five days; design assistance takes between 10 and 25, depending on provided materials and the complexity of the part.

Before completing your design, it should be evaluated for required considerations. Draft features, which facilitate part removal from a mold, are often overlooked during the design phase. Another example is surface finish — turnkey injection molders can achieve a number of finishes, but not all materials are ideal for all finishes. A third overlooked consideration is witness lines, which are marks left where different parts of the mold connect — your part should be designed so that witness lines occur only in non-critical areas.

Prototyping

Validating your design with a prototype ensures that the part is functional. We have additive manufacturing (3D printing plus other processes) capabilities for quick prototyping to save you time.

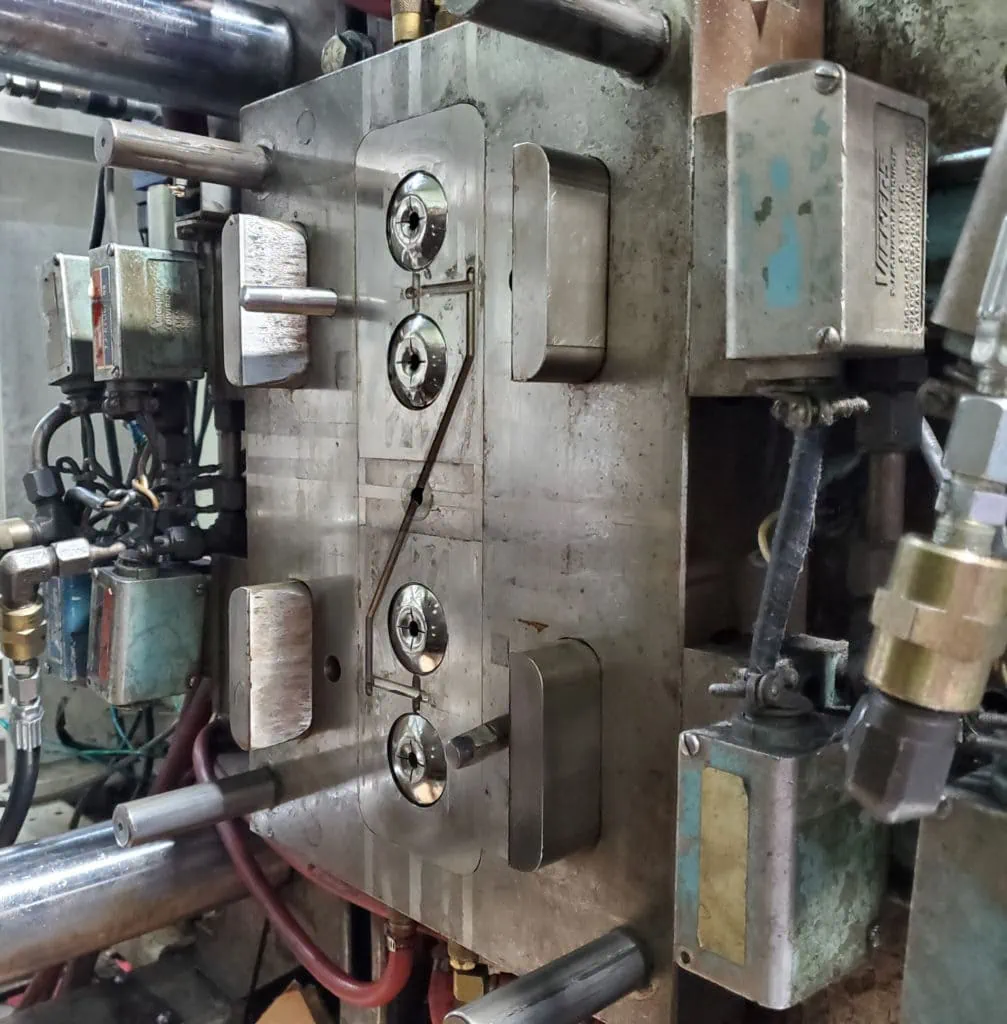

Tooling

After your initial design is approved by the customer, a production quote for part pricing and tooling is submitted. The quote will include all costs, including mold design and construction, other tooling costs, materials, and any additional services. We work to have a completed quote in-hand within two to three days once the part design has been finalized.

Meridian does use off-shore partners in addition to our in-house tooling department, dependent on size and complexity of projects. We do so by stating during the process if we are tooling domestically or off- shore with customer approval.

Meridian will generate Designs for Manufacturing (DFMs) for the part(s). DFMs integrate the product design and manufacturing planning into one cohesive process. The DFM is then submitted to customer for approval.

Once approved we begin the mold tooling. The mold tooling timeline varies depending on size and complexity of the product, but generally takes seven weeks or less.

T1 samples are made and provided for approval. If there are revisions, T2 samples are manufactured.

Once T1 or T2 samples are approved, production can begin. In the case of large molds that are tooled overseas, they are shipped to Meridian’s Dallas, Texas facility.